In 1996, the first in the industry through the certification of ISO9001 quality management system certification and ISO14001 environmental management system certification center China radius, and in 2008 passed the GJB9001A quality management system certification center certification of the new era. In 2010 through the certification center ISO9001:2008 certification standards for version.

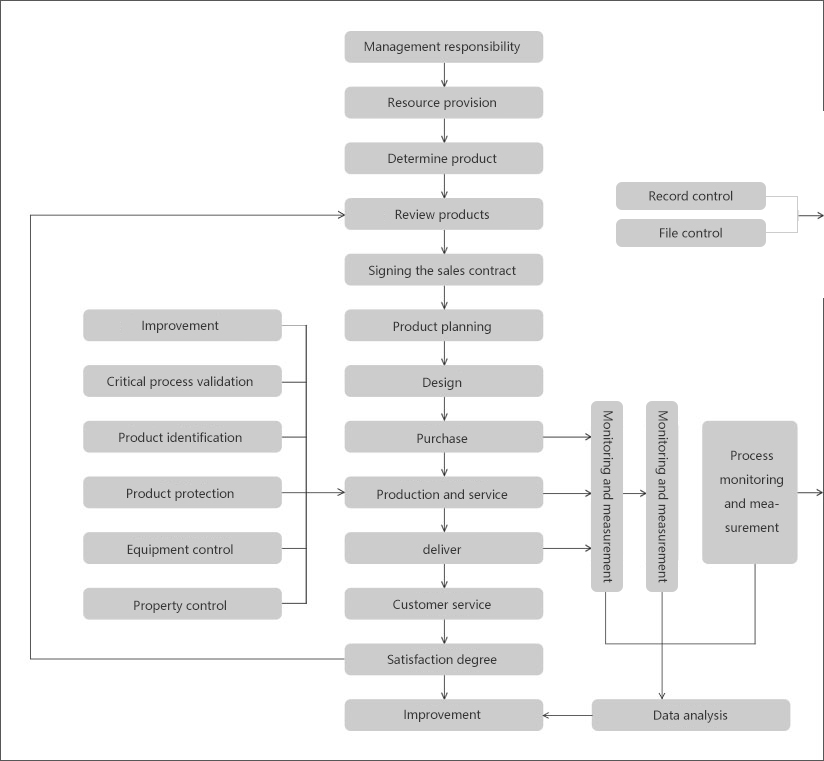

To establish a quality management system has 23 program files, according to the quality standard system of documents, records, production, information management, unqualified products, internal audit, customer satisfaction, corrective and preventive process specific requirements. Over the years the company strictly in accordance with the requirements of the quality management system for quality management, and constantly improve and upgrade the system, through the system of the rolling inspection, centralized audit, professional training, and promote the work of quality management system and gradually improve and perfect. The company set up factories without a major quality problem for 20 years, the effectiveness of quality system operation. In the course of operation of quality management system, strictly implement the PDCA management methods and concepts, quality management departments to establish a professional team and the implementation of quality management, step by step the quality responsibility system and self - signed mutual inspection and special inspection system to ensure that all levels and personnel quality consciousness and responsibility. The company set up a full range of customer service concept, service quality to product in the application, set up a professional technical service team, in-depth to the customer site and downstream customers to the customer site, professional anti rust technology for customer analysis of the cause of the problem, to provide system solutions, on-site training and guidance, antirust technology optimization, winning wide praise of the market. Companies operating in the process of combining the actual situation of the company and the market demand, constantly improving the quality of work, from the bottom up, from the inside are in place of taking quality as the core, take the customer as the focus to actively carry out strictly, quality, effective, by the Quality Supervision Bureau of Liaoning Province as an advanced unit of quality management.

The company has a technical center for product and technology development trend of domestic and international industry, pay close attention to, timely development of new products and new technologies with the market demand, the main product has reached the international advanced level; the quality management system and quality activities, strict product quality, ensure the products pass rate and reliability, product quality assurance ability to reach the domestic advanced level.